Once they have been produced, products often undergo a final finishing step. The aim of this final step is to increase their value or improve their visual appearance. Another frequent role of finishing processes is to improve the quality. The following list provides a brief overview of possible techniques:

- Hardening

- Deburring

- Cleaning

- Smoothing

- Applying a sheen

- Satin finishing

- Alloying

- Artificial aging

Injection-molded or blow-molded plastic parts often have burrs, which are not just unattractive, but also interfere with the function. When they are treated with hot air, these burrs can be almost completely removed.

Chocolate gets its characteristic sheen when it is treated with hot air during the final step of the manufacturing process. Another area where the visual appearance of the products plays a crucial role is the cosmetics industry. For example, it is hot air that creates the glossy surface finish found on lipsticks.

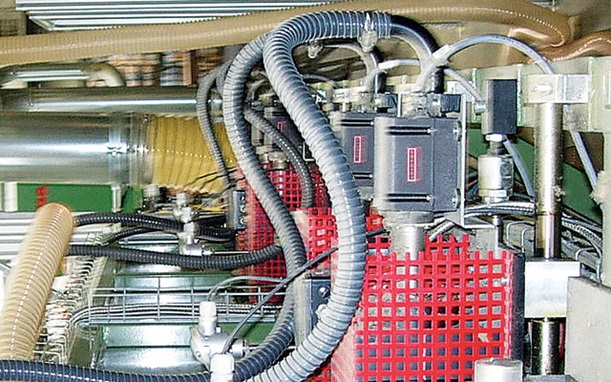

Leister has the solution

Leister has a very wide range of products and power ratings to cater for the many finishing processes that exist. This makes it easier to select the right components for optimum equipment and, in turn, optimum process control.