Thermoplastics can be heated up until they soften enough for you to reshape them. To ensure that the material is sufficiently flexible for the subsequent forming process, hot air is used to heat up either the entire component or just certain parts of it.

In principle, the deburring of injection-molded plastic components is also classed as a forming process. The fine but unattractive burrs are heated so that they melt and change shape due to the surface tension.

Any narrow strips of material that link several plastic parts or a sprue and a plastic part together at the end of the injection or blow molding process can be separated by targeting them with hot air.

Leister has the solution

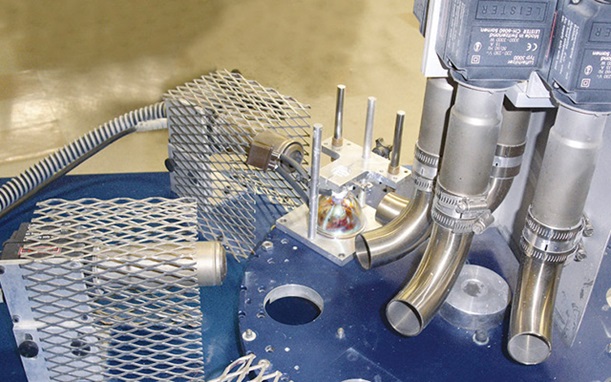

Leister air heaters and hot-air blowers are also used to heat up parts before they undergo forming processes. The wide power range means that you can select the optimum equipment for your process.

More application: