Hot air automatically springs to mind whenever we think about drying. The hot-air blowers, air heaters, and blowers from Leister are ideal for this. They are used for all kinds of drying applications. You can vary the air distribution and the flow rate depending on the desired drying results. This involves adapting parameters such as the temperature and air volume and using different nozzles.

When hot air is used for drying, two physical effects interact with one another. Together, these further increase the efficiency of the drying process: Firstly, hot air can hold considerably more moisture than cold air. Secondly, the continuous current of air that passes over the wet surface increases the level of evaporation, particularly if fresh, dry air is always used.

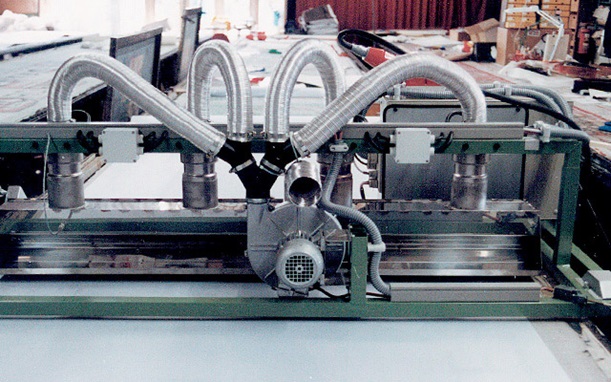

To make the drying process even more efficient, hot air is often used to blow off any drops of moisture that are resting lightly on the surface before the main drying process starts. Once again, Leister can offer a solution. This consists of a blow-off nozzle that was specially developed for this purpose plus the powerful AIRPACK blower.

Some examples of drying applications:

- Paper manufacture

- Textile production

- Manufacturing of nonwovens

- Metal, plastic, or glass components

- Packaging after cleaning

- Packaging before filling

- Bottles after filling

When "drying" is understood in its wider sense, you also have the processes of roasting and dehydrating on top of the numerous example applications listed above. For instance, Leister air heaters and blowers are used for roasting coffee.

Leister has the solution

Whatever you want to dry – Leister has the solution. Moisture can be blown away using the blow-off nozzles together with the AIRPACK high-pressure blower. For the purpose of drying wide paper webs, several LHS air heaters with wide slot nozzles can be combined and supplied with air by powerful Leister blowers.

More application: