It would be hard to think of a sector that uses as many variotherm processes for manufacturing and processing as the plastics industry does. Many of the process steps involved in producing plastic – as well as, in particular, the further processing that it must undergo and the manufacture of end products – call for repeated heating and cooling of the material. The processes are so diverse that they cannot all be described here.

However, the list of applications includes both preheating in advance of forming processes and the separation of sprues. By using hot air for deburring, you can dispense with the mechanical cutting tools that are subject to wear and the associated fluctuations in quality. Thermoplastics are brought up to temperature until they become soft and can be shaped. Thermosetting materials must be heated up during primary shaping to enable the cross-linking reaction. In the context of lightweight construction, what are known as "fiber-reinforced composites" are heated across the entire surface or at specific points. In this way, they can be shaped and joined with other components to create highly complex hybrid parts. Welding can be used to create secure connections between several components, thereby increasing their functional density.

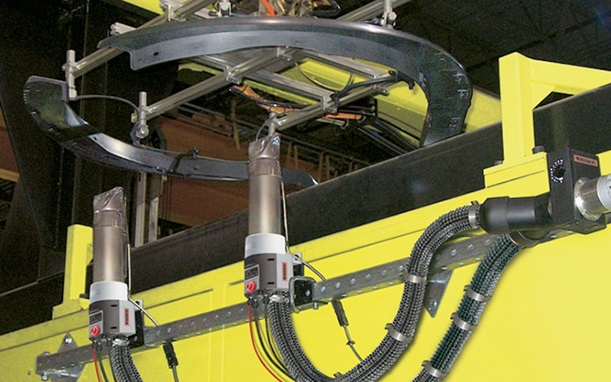

All these processes require heat, which can be supplied quickly and reliably by Leister hot-air tools.

Leister has the solution

Whether you are looking for air heaters, hot-air blowers, or accessories – Leister's large array of products, coupled with the wide power range, mean that you can choose the optimum equipment for a whole host of plastics processing operations.