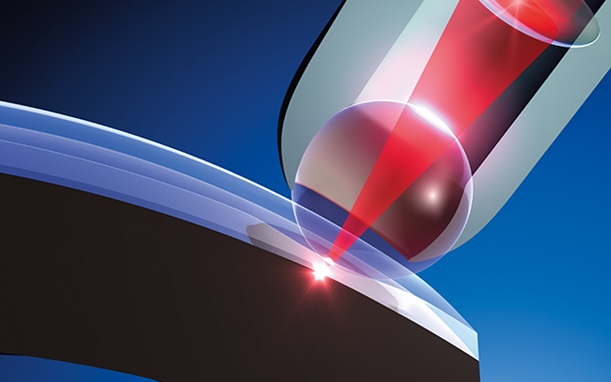

Our innovative laser systems for welding plastic make new methods possible in the automotive industry, the medical and sensor industries, electronics and micro-system technology. Every one of our developments defines the state of technological possibility. An internationally exclusive Leister specialty is the patented and award-winning "GLOBO Welding" that can weld three-dimensional plastic components in one step. We can find customized, cost-effective solutions for the most versatile jobs and customer demands. Our specialists assist you every step of the way, from design and construction to material selection and process optimizing and integration.

Leister has been the internationally leading provider of plastic welding machines for over 60 years. We have comprehensive theoretical and practical knowledge in plastics processing. We also have established ourselves in the market with our laser beam welding. Leister was one of the first companies to develop and manufacture laser systems for the welding plastics. Every one of our developments defines the state of technological possibility.

The broad range of laser welding concepts, developed by Leister engineers and technicians in our laboratory, have proven themselves in practice many times.

Leister Laser Plastic Welding is in the position to provide customized state-of-the-art solutions for our customers' problems.

Suitable materials

Almost all thermoplastic plastics and thermoplastic elastomers, including ABS, PA, PC, PP, PMMA, PS, PBT and fiberglass reinforced plastic types, can be welded with laser beam. The welding seam strength is comparable with that of the base material.

Transparent plastic can be welded to dark plastics which have preferably been colored with soot. Special pigments allow welding dark,dark and transparent/transparent combinations, as well as colored plastics.